> 고객센터 > 공지사항

> 고객센터 > 공지사항| 제 목 | : [Ystral]리튬이온배터리슬러리 파우더 혼합시스템 | ||

|---|---|---|---|

| 작 성 일 | : 2022-05-19 | ||

|

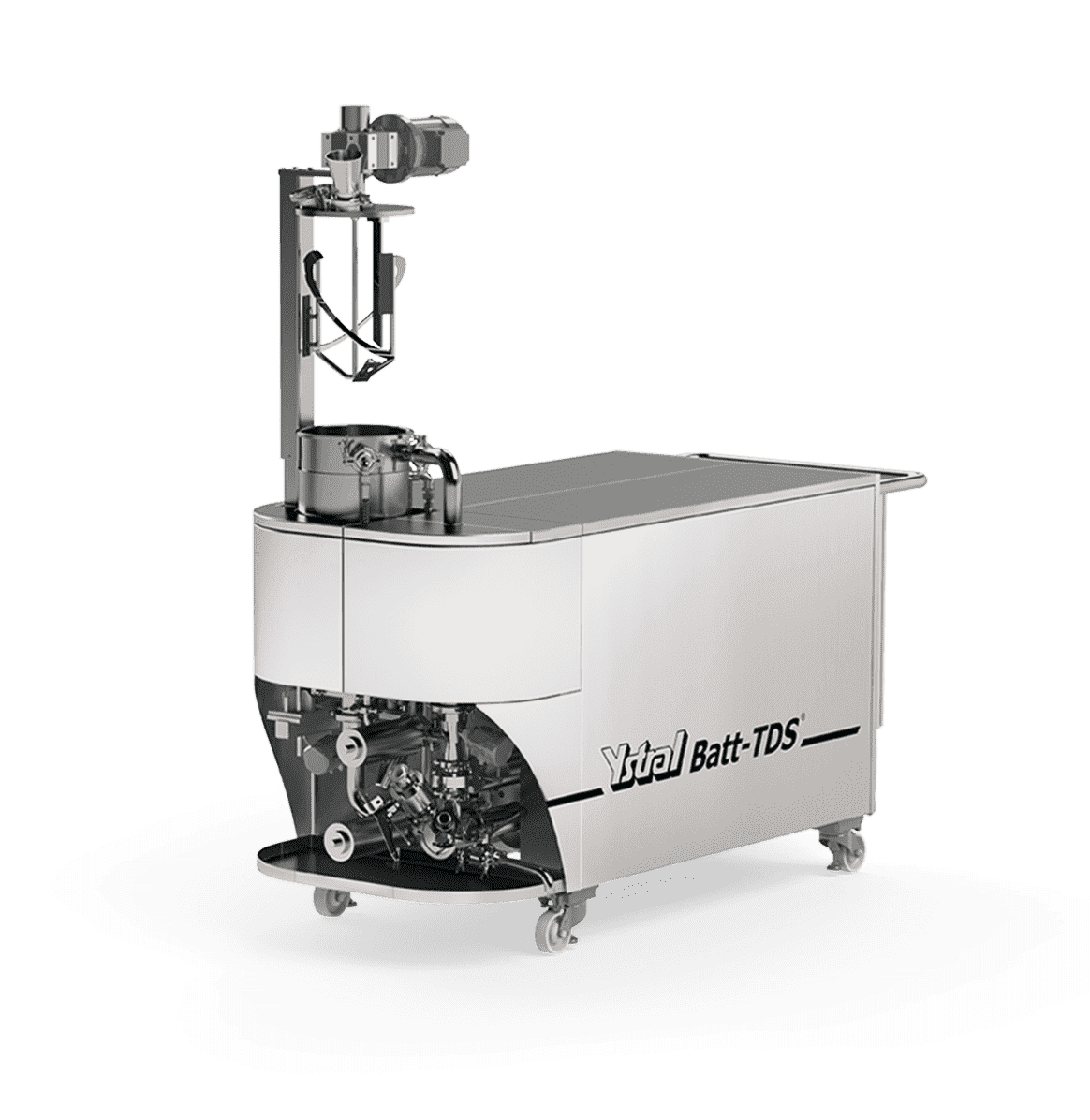

Supercharge your battery slurry process Ystral Batt-TDS Powder Dispersing Systems for lithium-ion battery slurry   Batt-TDS navi Accelerating lithium-ion battery R&D https://player.vimeo.com/video/566635612 <동영상 보기> Batt-TDS™ inducts powders under vacuum into a stream of liquid, thereby creating conditions for optimal dispersion of diverse components in a continuous sequence. Process sequence for slurry preparation with a Batt-TDS. a) Images of an attempt to dissolve Solef 5130 (Solvay) PVDF powder (8.2 wt%) in NMP for 60 min vs b) 3 min after powder induction with a Conti-TDS (<1 min) at room temperature. c) Illustration of deagglomeration of carbon black d) a C65 (Imerys) carbon black paste produced by dispersing carbon black in an NMP solution of PVDF (1:1 C65:Solef 5130, 11 wt% in NMP). Performance comparison of NMC 622 /graphite cells with cathodes made with a Batt-TDS for 1 min after powder induction vs a planetary mixer for 2.5 h: a) long-term cell cycling, b) internal resistance, c) Coulombic efficiency with 2C/3C charge/discharge rates, respectively. .jpg) |

|||